Our website uses cookies. We analyze usage statistics collected based on them and they may be used for targeting advertising on other websites.

You can also reject the tracking and use of cookies. More information

In spring 2022 we launched our new Koivu plant pots to give our clients a more sustainable option for their green design solutions. The Koivu pots are made from Finnish birch plywood at our small factory in Nastola, Finland. Here we tell you a little bit more about the manufacturing process, from design to a beautiful, finished product.

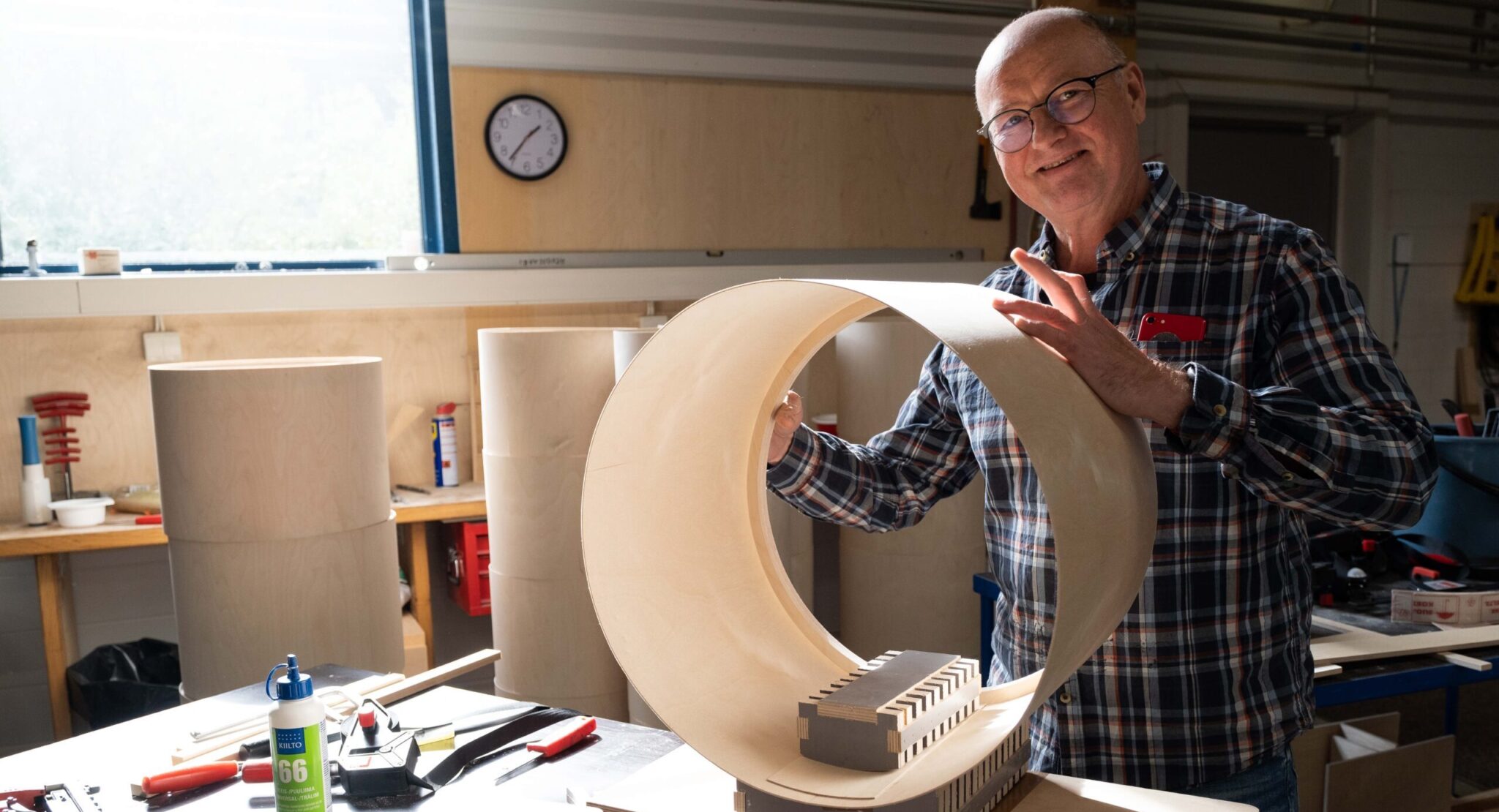

In Nastola, a municipality near Lahti, Finland, you can find a small factory where our Koivu plant pots are manufactured mostly by hand from Finnish plywood. Machines, such as waterjet cutters and power saws, play a part in the process, but our wood craftsman Heikki Saastamoinen and his team have the most important role. Together they make sure each pot is made with high quality.

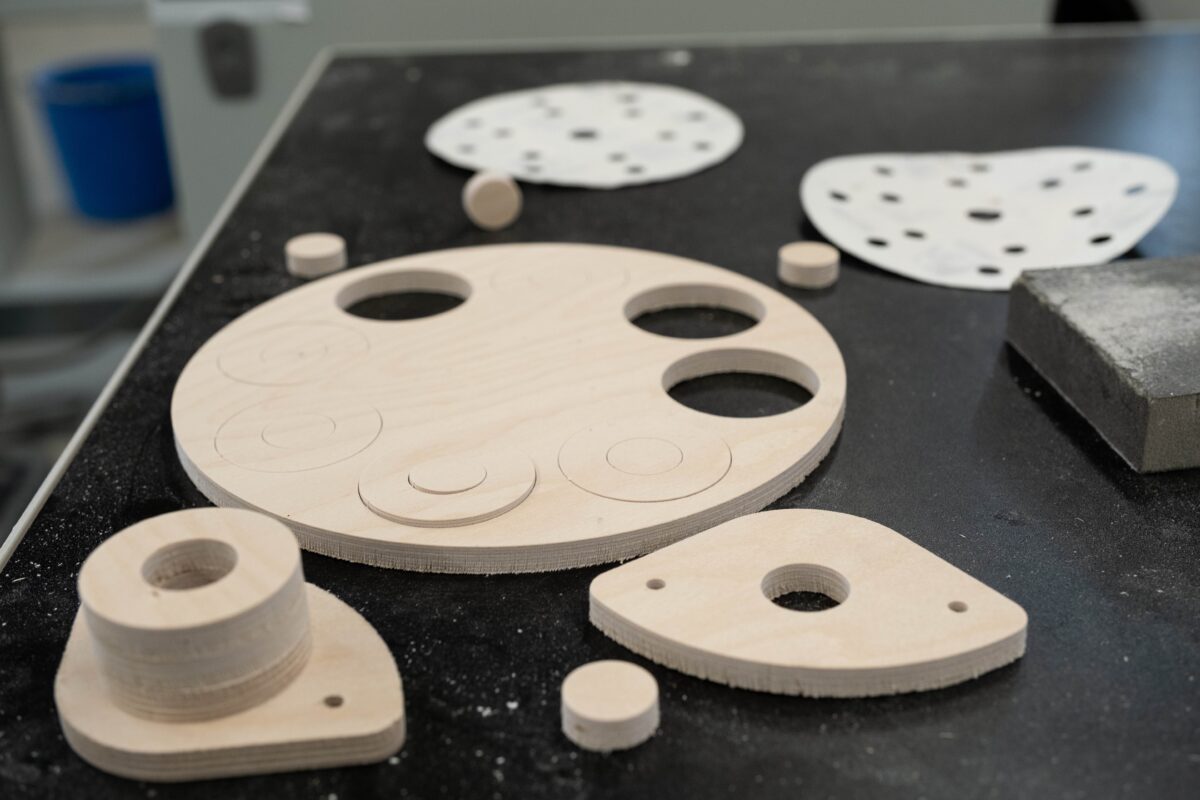

The manufacturing process begins with planning and drawing the design by hand to see what kind of parts are needed for the pot. The designs are uploaded into the waterjet cutter to create a model of the necessary pieces for the cutter.

The waterjet cutter uses, as the name suggests, high-pressure water to cut the pieces from the plywood. Information about the size and thickness of the plywood is entered into the machine as well as the drawings of the necessary pieces. The use of waterjet cutters has increased a lot in many fields, but in wood workshops it is not used much yet.

“Waterjet cutting has one major advantage – the jet of water is like a very thin blade, so it wastes less material when cutting, and the pieces can be cut right next to each other. This way we can utilize most of the material”, Saastamoinen explains.

The accurate cutting of the waterjet also makes it possible to create sharp inner corners, which is tricky with other blades. There are no limits to which shapes can be created. The waterjet also creates a very clean cutting edge with no grinding marks.

Another tool that is used to make the pots is a circular saw. Before using the saw, the dimensions for the pieces are checked manually to make sure that the wall of the pot is exactly the right size.

Machines can help with cutting the pieces for the pots, but they can’t assemble, glue together or finish materials. The Koivu plant pots don’t just pop out of a machine as a finished product.

The wall of the pots is bended and glued by hand, using moulds and a proper type of glue. The glue traces are then sanded off. The finishing touches are also made by hand – the thin veneer cannot be finished with a machine, as the sensitive material might break. A skilled wood craftsman, however, can finish dozens of pots a day. At the same time, they carefully go through all the seams to check the quality of each pot.

Finally, the surface of the pot is treated to create the desired finish. The natural wood colour requires two coats of wax and is the fastest to finish. The coloured pots require three to four layers of wax. The wax is applied with a sponge and the surface is polished between every layer. The last step is to attach the legs or pads before sending the pots on their way to their new homes.

It has been a long journey from an idea to a finished product, but the production is now fully up and running. Heikki Saastamoinen has a clear vision about how to develop the manufacturing process even further to make it faster, without sacrificing high quality. The more pots are ordered, the more opportunities there are to develop the factory. At the core of the work, however, is cooperation and skilled professionals – the collaboration between InnoGreen and Saastamoinen has made it possible to create an innovative product such as the Koivu plant pot, and together they continue to make it even better.

Did you know that the same factory also builds our green stops? The large modules are cut with machines but assembled by hand. It takes one working day to create one module, with up to 70 separate pieces and over a thousand steps in the woodworking process. Building a green stop is like putting together a big jigsaw puzzle, and there is a huge number of different joints.

Interested in the Koivu plant pots or green stops? Contact us and we’ll gladly tell you more!